Industry 4.0 is the fourth industrial revolution, characterized by the integration of modern technologies in manufacturing and industrial processes.

With constant technological advancements, we have finally entered the era of Industry 4.0, or we can say, the fourth industrial revolution. You may ask, “How does it differ from the previous ones?” Well, Industry 4.0 is characterized by the integration of digital technologies and advanced automation into manufacturing.

If we discuss numbers, the global market for the fourth industrial revolution is experiencing a tremendous surge and is projected to reach $781.51 billion by 2033. (Straits Research: Industry 4.0)

Curious to know more about it, you are at the right place. In this post, we will dive deeper into the fourth industrial revolution and understand how the integration of tech and modern automation affects the manufacturing industry.

KEY TAKEAWAYS

- Industry 4.0 is the new era of manufacturing and industrial processes.

- The fourth industrial revolution is characterized by the integration of advanced technologies like IoT, AI, and machine learning.

- Companies have started advanced laser beam welding to deliver better results.

- Modern innovations enhance precision and efficiency with smart manufacturing practices.

- With more advancements and digitalization in the industry, online threats have become more common than ever, highlighting the importance of digital security. Industry 4.0 and sustainability are converging. Organizations are following more environmentally friendly ways.

The fourth industrial revolution is based on smart infrastructure and the creation of intelligent factors. Its major objective is to enhance operational efficiency, flexibility, and productivity. In addition to that, it also allows organizations to make intelligent and better decisions.

If we specifically talk about the welding sector, advanced and new innovations have transformed everything. Organizations now use fully automated and collaborative machines that enhance speed, accuracy, precision, control, and overall weld quality.

Companies these days perform an advanced version of welding, laser beam weld. It is a fusion welding process that uses a focused laser beam to join materials. This technique is much more effective than the conventional ways. Due to its precision, speed, and ability to create strong narrow welds, laser beam welding is becoming a popular choice across different industries.

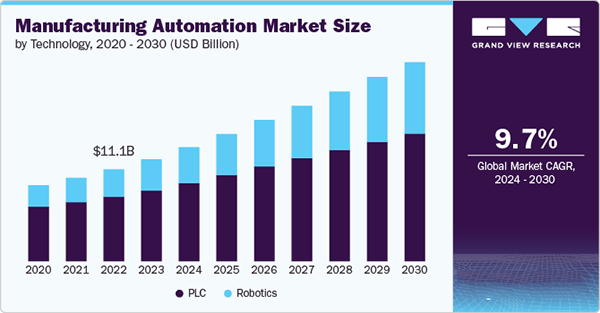

Apart from welding, if we talk about automation in the whole manufacturing industry, the market is on the rise and is expected to grow at a CAGR of 9.7% after being valued at $11.1 billion in 2022.

The manufacturing sector is always under constant pressure to meet the rising demands, and at the same time bring more cost efficiency to the services. Internet of Things (IoT) plays an extremely important role in achieving this goal. Here is how IoT influences industrial processes:

These four points highlight the important role the Internet of Things (IoT) plays in industrial processes.

Almost all the industries are shifting to smart ways of performing tasks. If we talk about the manufacturing sector, companies are now integrating modern technologies like AI and machine learning to streamline processes and work efficiently.

Now, routine tasks can be handled by the new innovations, securing plenty of time for employees to focus on more creative aspects of the work, bringing operational efficiency.

In addition to that, it also minimizes the chances of human error and increases precision.

As hinted above, AI and machine learning prove to be two of the most useful technologies in the industrial process, providing several perks:

This is how AI and machine learning serve as important elements of the manufacturing industry.

In this era of digitalization, when anything and everything is on the internet, cybersecurity often becomes a matter of concern for industries across various sectors. If we talk about Industry 4.0, it heavily relies on IoT and interconnected systems, making them more susceptible to online attacks that can lead to severe consequences.

Additionally, manufacturing units are required to deal with the excessive volume of sensitive data. Hence, it is extremely important for them to take all the suitable measures to ensure cybersecurity. This is necessary to maintain a positive reputation in the market and build consumer trust.

DO YOU KNOW?

86% of manufacturing executives anticipate that generative AI and smart factory solutions will be the primary drivers of competitiveness.

With the increasing environmental awareness, all the sectors are inclining towards sustainable ways. Industry 4.0 and sustainability are also converging in order to perform tasks in a much more environmentally friendly manner.

The fourth industrial revolution covers advanced technologies like AI, machine learning, big data analysis, etc. These help ensure better resource management, reduced waste, and increased efficiency, helping manufacturers save energy and resources.

Additionally, many organizations implement specific waste reduction strategies based on their field to further reduce their environmental impact.

In conclusion, Industry 4.0 is another big leap towards more efficient, productive, precise, and sustainable practices in the manufacturing and industrial sector. It is characterized by the integration of advanced technologies like IoT, AI, and machine learning.

With these tools, the welding technologies in manufacturing have significantly enhanced. One of the innovations in it is the laser beam welding, offering more precision and strong welds. Looking ahead, as new innovations and integrations make their way to the manufacturing industry, this sector is only set to flourish in the future.

Industry 4.0 is the fourth industrial revolution, characterized by the integration of modern technologies in manufacturing and industrial processes.

Laser beam welding is a fusion welding process in which, high-energy-density laser beam is used to join metals.

Smart manufacturing is a fully integrated and collaborative manufacturing system capable of meeting the industry demand and responding in real-time.

No, they are not the same, but smart manufacturing can be considered a subset of Industry 4.0 that is only concerned with leveraging smart innovations to improve the manufacturing procedures.